Products

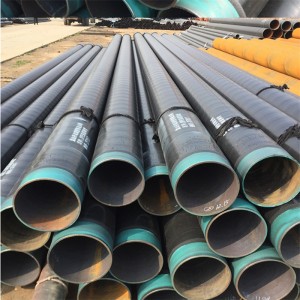

Anticorrosion For Petroleum Pipeline

Specification

DN50-DN1420mm

3LPE: three-layer polyethylene

2LPE: double-layer polyethylene

FBE: single-layer epoxy powder

2FBE: double-layer epoxy powder

Anticorrosive Coating Thickness of 3LPE

| DN Nominal Diameter | Epoxy Coating(μm) | Adhesive Coating(μm) | Total Coating Thickness(mm) | |

| (mm) | Normal(n) | Reinforced(v) | ||

| DN≤100 | ≥120 | ≥170 | 1.8 | 2.5 |

| 100<DN≤250 | 2.0 | 2.7 | ||

| 250<DN<500 | 2.2 | 2.9 | ||

| 500≤DN<800 | 2.5 | 3.2 | ||

| DN≥800 | 3.0 | 3.7 | ||

The pipes of oil pipelines are generally steel tubes, which are connected by welding and flanges and other connecting devices with long distance pipelines, and valves are used for opening and closing control and flow regulation. Oil pipeline mainly has isothermal transportation, heating transportation and sequential transportation and other transportation technology. Corrosion of pipeline and how to prevent corrosion is one of the important links of pipeline maintenance. Because the oil contained sulfur and acid, and the pipeline exposed in the open air by wind and rain, the pipeline is easy to be corroded. Pipeline corrosion mainly has the following kinds: steel oxygen corrosion caused by the principle of galvanic cell; Hydrogen evolution corrosion due to acid rain caused by extremely acidic sulfides (sulfur dioxide and hydrogen sulfide) on pipeline surface; Carbon dioxide acid corrosion caused by atmospheric precipitation; Bacterial corrosion caused by bacteria that can metabolize sulfate on the surface of the pipeline and corrosion caused by water in the pipeline.

The pipe used for oil pipelines is mainly carbon steel pipe, which can be divided into seamless steel pipe and welded steel pipe according to its manufacturing process. Seamless steel pipe has the characteristics of high strength, multiple specifications, so it is suitable for corrosive oil products or high temperature conditions. Seamless steel pipe is divided into hot rolled and cold drawn two kinds. Because cold drawing process will cause hardening of the material, it is also necessary to do the corresponding heat treatment according to the specific use of the pipe. Welded steel pipe can be divided into two kinds: seam steel pipe and dropped welded pipe. Due to the process characteristics of carbon steel pipe, this kind of steel pipe is easy to become brittle at low temperature, so it is mainly suitable for normal temperature pipeline, the use temperature of the pipe should not exceed 300 degrees Celsius, generally speaking, the use temperature of ordinary carbon steel pipe is between 0 and 300 degrees Celsius. If the use of high quality carbon steel pipe, the temperature range and relaxation of - 40 to 450 degrees Celsius.